If your welding process is flame welding, cold weather and inclement weather in general can cause problems. The latter appear during the work itself, but can also call into question the quality of the welds in the long term. Besides the discomfort for the welder, it is important to take some precautions to protect your equipment and adopt a specific method to achieve a quality welding. Here are some tips to make welding easier in cold weather.

Welding equipment and gas in cold weather

The first consequence of cold weather is on your flashlight. Start by checking the user’s manual to see if a minimum temperature is specified.

Choose a gas compatible with sub-zero temperatures

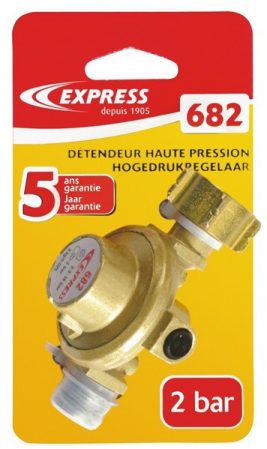

As for your welding gas, if you are using propane or acetylene, these can withstand outside temperatures as low as -30°C, giving you plenty of room to maneuver. On the other hand, butane becomes difficult to use as soon as the temperatures are negative. It begins to liquefy, which affects the gas flow rate and flame pressure.

Store everything you can in an area where the temperature remains positive

It is important to store your flashlight and gas away from the cold. If you have the opportunity, also store your metal parts to be welded. These will be less easy to work with if they are frozen, especially since you have to take into account the condensation that forms with temperature differences.

If you are welding outside, you have no choice but to work on cold or even frozen material, here is how to proceed.

Precautions to take when welding in cold weather

- In cold weather, the welds cool down more quickly, which increases the risk of cracking and makes them considerably more fragile. You must preheat your metal before welding, using your flashlight or a hot air gun. By increasing the temperature of the parts, you make it easier to melt the metals.

- Take shelter from the wind! If it’s not only cold, but also windy, you need to protect yourself from it, as it aggravates temperature-related problems.

- Increase the temperature of your flashlight to compensate for the cold.

- You can also play with the concentration of the flame to focus the heat on a specific point.

- Allow more time than usual. By welding slowly, your metal takes advantage of the warm air to get to a warmer temperature. Heated in the mass, it will cool more slowly, which is beneficial for the quality of the weld.

- When using filler metal, you must ensure that it is compatible with the parts you are about to weld. With proper melting temperatures for each part, you will get a better bond.

- Study the physical properties of your metals. Especially consider their ability to shrink with cold. In particular, it can make it more difficult to fit the parts together. You must therefore take particular care to position each of the parts before starting the work.

Limits not to be exceeded

While it is possible to weld in cold weather, you must set limits for yourself. If the weather turns out to be particularly windy, with rain or even snow, it is preferable to postpone your work. You are jeopardizing the quality of your work which will be less and therefore become more fragile over time. You are also putting your health at risk.

Produits associés

-

42,30€ HT

Classic Lamp’ Express blowlamp 511

Blowlamp with sharp tip burner. Usable in low temperature. Ideal for thawing.

Produits associés à cet article disponible sur express.fr

-

354,40€ HT

Koro oxyacetylene kit Cat. No. 2905

Initially designed to provide plumbers and refrigeration engineers with a tool that... -

243,21€ HT

Plumbing pack 6073

The plumbing pack comprises of a torch with swivel attachment and turbo burner.