Since its creation in 1905, the Guilbert Express company has never stopped innovating. The company develops ranges of heating tools for brazing and soldering, but also all the devices for roofers, farmers (for thermal dehorning), landscapers and municipal employees (thermal weed burner), construction workers (ground marking), etc. It also supplies all the do-it-yourselfers who need at home heating guns, thermal scrapers or soldering irons, which are reliable, convenient to use and easy to maintain. It even supplied the burner for the Olympic flame at the Albertville Games! It is also the originator of the Cercoflam burner.

The R & D Department – Research and Development of Guilbert Express

The Guilbert company was born out of innovation. In 1905, Léon Guilbert, its founder, filed his first patent at the same time as he founded the company. It was a “heating and burning appliance”. The following year, two other patents which were filed, announced a desire to revolutionize brazing and soldering tools that has never failed since.

Guilbert has nearly 60 patents from its research and development department and its devices are sold worldwide. Engineers and technicians working in research systematically involve the user, who is the only one who can express his specific needs. The policy of the R & D department is always the same: listen, understand and innovate.

1972: the birth of the patented Cercoflam burner

The 5% turnover dedicated to research at Guilbert Express has led to the development of a technology that has revolutionised the world of copper brazing, or any other brazing, as well as brazing welding: the patented Cercoflam burner.

The engineers at Guilbert Express are always looking for new techniques to simplify the work of the users, so they wanted to design a tool that would distribute the heat evenly around the copper tube to obtain the best possible braze. This is how the Cercoflam process came about. Very popular in the sanitary field for copper brazing, it is nevertheless used in many other fields.

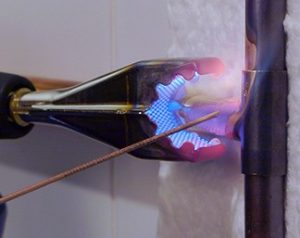

The Cercoflam device generates a flame that has the particularity of licking the entire perimeter of the tip and its interior. It can therefore heat all the parts on which the welder is working. This innovation benefits professionals who can work much faster, obtaining perfect finishes. For the occasional welder, Cercoflam makes it easy to do a professional job without having experience.

With Cercoflam, heating is fast and the flame is not visible.

How to use the Cercoflam tip

Thanks to the internal combustion in the device, the flame is not visible. This allows the welder to work outdoors and in strong winds without being hindered.

In addition, the system is designed to consume less gas. This allows for cost savings and longer working autonomy. Another advantage of the Cercoflam burner is that, despite its low consumption, it heats up very quickly. The heating technique has been optimised, as has the system, which makes it much easier to go all the way around the pipes to be welded or brazed, while maintaining perfect heating homogeneity.

Finally, the Cercoflam burner is quieter than most other devices.