There are many advantages to using a gas torch. The tool is multi-purpose, suitable for a broad spectrum of applications, ensuring high-quality joints for tasks ranging from minor domestic plumbing to large-scale industrial projects. Let’s take a look at why you should choose this type of torch.

1. Transport, logistics and ease of use

Working with a gas torch gives you great mobility. For plumbing work, for instance, you would opt for a small torch with an integrated gas cartridge or one that can be worn on your belt, allowing for easy mobility and access in various locations. In this case, butane or propane gas is used.

For more extensive usage, the gas torch will be connected to a larger gas cylinder, providing greater autonomy. This cylinder is typically mounted on a wheeled trolley for easy maneuverability. You will then use an oxyacetylene torch, which requires two gas cylinders: one of oxygen (the oxidiser) and the other of acetylene (the fuel).

Thanks to the precise adjustment of its flame temperature, an oxyacetylene torch is suitable for all types of work, whether or not you use a filler metal: brazing, autogenous welding, tin soldering, plumbing including PVC pipes, etc.

The level of mobility offered by a gas torch is not achievable with an electric torch. This necessitates a battery with limited autonomy, which also adds weight to your tool, or the need for a nearby electrical connection. In addition, the use of electricity poses safety problems, particularly outdoors, depending on the weather, and on sites exposed to damp.

The manoeuvrability of a gas torch in all circumstances and its light weight make it extremely comfortable to use. Moreover, welding under optimal conditions is key to ensuring the quality of the joints.

2. Controlling the flame temperature

Controlling the flame temperature of your gas torch is crucial to the quality of your joints, whether brazing or welding.

Controlling the melting point

By adjusting the flame temperature, you can precisely control the level of heat applied to the material to be welded. This is essential to ensure that the metal melts properly without overheating, thereby minimising the risk of damaging the structure of the material.

Adaptability to different metals

Metals have different melting points. This is especially true in brazing, where you need to take into account the melting points of both the parts to be joined, as well as the filler metal.

With a gas torch, you can adapt to the specific characteristics of each metal, avoid weld defects and ensure the robustness of your joints.

3. Choice of gas

You can choose between a single-gas torch (butane or propane) or an oxyacetylene torch, which uses two gases, oxygen and acetylene. The choice of gas depends on a number of factors, including the type of welding work to be carried out, working conditions and your preferences.

1 – Butane is suitable for light applications. It offers a relatively hot flame, suitable for brazing and soldering work. It is not recommended for welding work requiring higher temperatures.

2 – With a slightly higher flame temperature, propane offers greater versatility.

3 – Acetylene and oxygen generate a much hotter flame, making it possible to weld metals with a higher melting point, as well as large-scale work on larger, thicker parts.

4 – Finally, some soldering stations combine oxygen and butane/propane, making them oxy-gas stations that are often very practical for DIY enthusiasts who want a high-performance product at a lower cost.

Produits associés

-

28,10€ HT

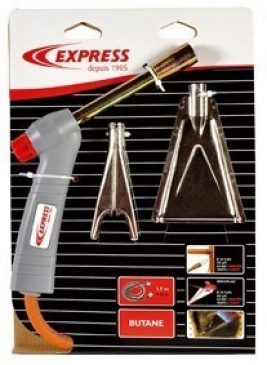

Plumber torch Cat. No. 5200 with all its accessories

Plumbing professional torch Cat. No. 5200, a standard that will render many services...

Produits associés à cet article disponible sur express.fr

-

Koro oxyacetylene station Cat. No. 2907

Initially designed to give plumbers and refrigeration engineers access to the best... -

88,82€ HT

Piezo blowlamp 351

Piezo blowlamp 351, plumber torch with capacity to be used in all positions with gas... -